SNAP® I2M In Action

SNAP I2M can be integrated with any number of external data sources and target applications.

To help illustrate the flexibility that this model implies, we've put together a series of short case studies using three very different scenarios.

Program Management Case Study

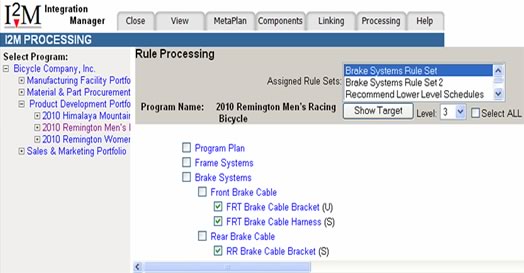

An automotive OEM with a portfolio of over 1000 product introductions in the next five years needs a global program management solution. SNAP I2M can be configured to:

- Receive incoming portfolio plans, and part / tooling information from multiple systems.

- Organize data by program in a structured hierarchy (the metaplan)

- Create user-defined business logic (rules) to assess metaplan components, identify required schedules and recommend schedule templates

- Allow users to apply rules to create new schedules in their scheduling application.

- SNAP I2M can be configured to integrate with a variety of enterprise scheduling products.

- Link schedules together

using rules that consider shared attributes, product development

processes and business practices.

Result: A set of best-practice integrated schedules that can be quickly put in place to support program ramp up and on-going management.

Top

Product Design Case Study

A manufacturer encourages widespread re-use of engineering designs for it’s product components to reduce costs, ensure high quality and continuous improvement. SNAP I2M can be configured to:

- Receive incoming part and tool information from Bill of Materials systems

- Organize data based on the corporate product breakdown structure (the metaplan)

- Include user defined business logic (rules) to assess metaplan components, suggest required product designs and recommend a predefined engineering solution

- Allow users to apply rules to create

new designs and data files in their existing EDM application. Designs

are created using stored procedures, enabling integration with a

variety of enterprise EDM products.

Result: A set of best-practice product designs that can be quickly put in place to support program ramp up.

Top

Manufacturing Specifications Case Study

A manufacturer prepares a set of program manufacturing specifications that ensure product designs are buildable, support best practices and consider plant requirements. SNAP® I2M can be configured to:

- Receive incoming part and tool information from EDM, Bill of Materials or Master Part List systems

- Organize data based on the product architecture and product program (the metaplan)

- Include user defined business logic (rules) to assess metaplan components, suggest required manufacturing specifications and recommend a best practice Bill of Process

- Allow

users to apply rules to create manufacturing specifications and related

data files in their existing application. Specification are created

using stored procedures, enabling integration with a variety of enterprise

requirement products.

Result: A best-practice Bill of Process that can be quickly put in place to ensure product manufacturability and program success.

Top